WORLD OF INDUSTRIES 05/2018 (EN)

- Text

- Innovation

- Industries

- Manufacturing

- Laser

- Solutions

- Logistics

- Global

- Automation

- Bending

- Industrial

A compact self-contained

A compact self-contained CLSP servo drive with higher efficiency from Voith Voith presents it’s new self-contained closed loop 4Q pump (CLSP) servo drive, a hydraulic linear axis from the product family of self-contained drives. The high energy efficiency, overload protection, and virtually wear-free operation, are all characteristic features of the CLSP. It also boasts automatic, load-dependent shifting of the hydraulic transmission. This reduces the connected load of the drive. As a result, the motor and inverter sizes are further more compact. This servo drive can be used for all direct linear motions, particularly when dynamic response, repeatability and reliability are required. The drive operates with a force of up to 500 kN and combines speed with robustness. The CLSP is typically used in the automation of all types of linear motion, handling, and machines with bending, cutting and forming processes. It consists of 3 main components: The servo motor, a 4Q internal gear pump, and a directly coupled hydraulic cylinder. No hydraulic power pack or oil tank is required for operating the self-contained drive. www.voith.com Wittenstein showcases the new Galaxie gearbox generation The Galaxie D drive system is a compact mechatronic unit comprised of a Galaxie G hollow-shaft gearbox and a special permanent magnet, high performance synchronous motor. The newest variant in the product family – the Galaxie DF drive system – boasts up to 30 % reduction in length compared to the Galaxie D. This space saving is possible because the motor is positioned radially around the gearbox. The Galaxie GH was launched for areas wherever the space for the length of the driven axis is limited. The right-angle version offers the same performance as the Galaxie G, so that the drive design is not compromised in any way. The new Galaxie D Drive System in size 085 is designed for use in axes with very high compactness and precision requirements. It also particularly targets applications where high torsional rigidity and freedom from backlash are called for rather than torque. Even in this compact version, the Galaxie D is still superior on principle: compared to a strain wave gearbox with approximately equivalent performance, it delivers three times better torsional rigidity – and one and a half times the maximum output speed. www.wittenstein.de/en-en Flender’s DX500: a step forward towards digitalisation of drive solutions Smart servo axis for effective and flexible production PRODUCTS At the Achema show in Frankfurt, Germany, the gear manufacturing company Flender, launched its new DX500 product along with the DX Assist app. The new smart sensor is a plug & play solution for measurement of vibrations and temperatures on the gear unit and notifies the system operator of any irregularities via the app straight to the smartphone. This enables predictive maintenance work before a need for unscheduled interruptions or stoppages in the production process arises. The temperature and vibration sensor measures and monitors parameters on the gear unit itself and indicates changes by means of LED signals and an alarm signal in the DX Assist app. www.flender.com SiEddy current sensors with high precision measurement The powerful inductive displacement sensors based on eddy currents provide high precision measurements of displacement, distance and position and can withstand pressure, dirt and oil even in harsh environments. In addition to the M12 design, the compact eddyNCDT 3001 eddy current sensor from Micro-Epsilon is now also available in M18 with measuring ranges of 6 and 8 mm. The sensors are protected to IP67 and are temperature-compensated up to 70°C. The high measurement accuracy, linearity and high frequency response rate of 5 kHz are outstanding characteristics. eddyNCDT sensors are factorycalibrated for ferromagnetic and non-ferromagnetic objects such as aluminum and steel. They are easy to use and they are particularly suitable for high volume and OEM applications as well as for salt water in offshore/marine applications. www.micro-epsilon.com Lenze, the leading automation company for the machine-building industry, has come up with a scalable drive solution for production and intralogistics systems. The combination of an i950 servo inverter, an m850 synchronous motor and a g700 planetary gearbox is easy to handle and facilitates cost-effective production, even for batch size 1. At the heart of the solution is the smart i950 servo inverter. Its greater computing power and the integrated EtherCAT-Port make it possible to control multiple axes synchronously at high speed, enabling it to complete complex tasks. The second component is the m850 synchronous motor. It stands out because of the favorable ratio between the mass inertia of load and motor, which results in very quiet running. Despite the high mass inertia, it is dynamic enough to handle medium to high loads. The drive is available in 3 sizes, each in 3 different power classes that extend from 2.0 kW to 9.2 kW. The g700 planetary gearbox is adapted for these motor characteristics and meets the requirements of medium-performance applications in terms of rigidity and high dynamics. www.lenze.com 32 WORLD OF INDUSTRIES 2018

WEG launches features to enable easy real-time monitoring of electric motors WEG, a leading manufacturer of drive technology products, has launched WEG Motor Scan, a solution for remote monitoring of electric motors at the Achema show in Frankfurt, Germany. This new feature enables cost-effective real-time monitoring and planning of predictive maintenance activities of WEG electric motors. This helps users to reduce costs and improve the availability of their machines. The compact WEG Motor Scan module measures surface temperature, motor vibration and operating time. Built with IP66 protection rating, the module has a battery life of 3 years and can work reliably from -40 to +80 C. The collected data is sent to a secure cloud, where it can be accessed by a mobile app or a web portal – the WEG IoT platform. This platform provides extensive analysis tools for fault diagnosis and triggers alarms in case specific values are exceeded. It allows maintenance staff to call up real-time data on current motor performance anywhere using a smartphone, analyse the data directly with the app or web portal, and take appropriate action. Future versions will be able to acquire and analyze data on energy efficiency and motor conditions (imbalance, misalignment and bearing condition). www.weg.net High performance brushless DC-servomotors from Faulhaber The BHx series from Faulhaber are new high power slotless brushless motors in 16 mm diameter based on a 2-pole technology. The series is designed for high speed and high torque both. The 1660 BHS series can operate at speeds up to 100,000 rpm and deliver an exceptional power of 96 W. It is the ideal solution for devices running for long period of time while preserving a low housing temperature like for high speed handtools. The 1660 BHT series can provide a continuous output torque close to 19 mNm with the ability to manage variable loads. Their flat speed-torque curve is as low as 95 rpm/mNm and helps to minimize speed fluctuation to ensure constant speed and smooth behavior. Those attributes make the 1660 BHT series the perfect solution for recurring intermittent use with high dynamic and also for accurate positioning. With their long form factor and low-vibration and quiet operation, both 1660 BHS and BHT series are particularly well suited for quiet hand tools, which reduce user fatigue. The low rotor inertia enables fine motor control by drive electronics and makes their operation very smooth. www.faulhaber.com Completely integrated series of absolute encoders from Dunkermotoren Single and multi-turn absolute encoders are simply indispensable for industrial automation. Especially in big machines, the encoders save referencing and allow a quick machine start. With absolute encoders, reference switches and limit switches as well as the associated cabling are no longer necessary. At last year’s SPS IPC Drives in Nuremberg, the company Dunkermotoren launched its latest generation of fully integrated absolute encoders. The AE 38 can also be integrated into the BG 45, unlike its predecessor, the AE 65. Instead of 12 bit multi-turn, the AE 38 realizes 16 bit multi-turn, and even 32 bit on request. With 16 bit multiturn resolution it’s already possible for the motor to run for almost 24 hours in one direction with nominal speed, without overflow of the multi-turn revolution counter. The AE 38 works using the energy harvesting principle. This means it does not need a life-time limiting battery or a mechanical gearbox. Within the modular system of Dunkermotoren, the AE 38 can be integrated into the BG 45, BG 65(S), BG 75 and BG 95 series. www.dunkermotoren.com Quick power packs ROBA ® -linearstop – perfect safety brakes and clamping units for linearly moved axes www.mayr.com your reliable partner MAYR.indd 1 03.07.2018 07:42:34 WORLD OF INDUSTRIES 2018 33

- Page 1 and 2: www.world-of-industries.com Viable

- Page 3 and 4: EDITORIAL The next stage of Industr

- Page 6 and 7: TABLE OF CONTENT 10 18 22 28 38 26

- Page 8 and 9: W RLDWIDE NEWS New sales director w

- Page 10 and 11: New DHL Americas Innovation Center

- Page 12 and 13: U.S. manufacturing sector now in re

- Page 14 and 15: New control platform opens the way

- Page 16 and 17: 02 Representation of the PLCnext Te

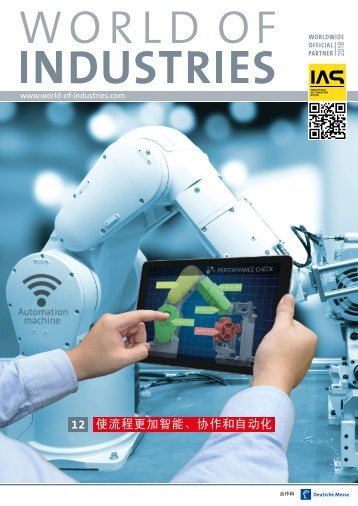

- Page 18 and 19: Bending without breaking AUTOMATION

- Page 20 and 21: Sweet pleasure, fabulous taste and

- Page 22 and 23: Simplifying Maintenance & Managemen

- Page 24 and 25: Modular and simply safety door prot

- Page 26 and 27: New age drive technology systems wi

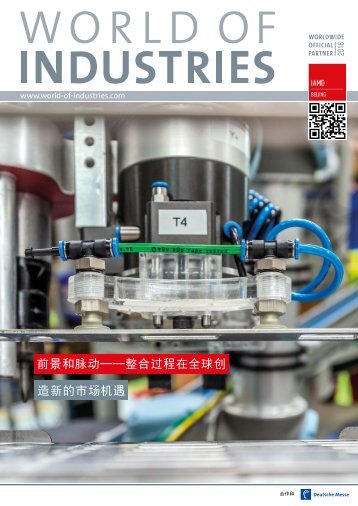

- Page 28 and 29: Continuous Growth Trajectory MOTION

- Page 30 and 31: MOTION AND DRIVES 02 Eight new honi

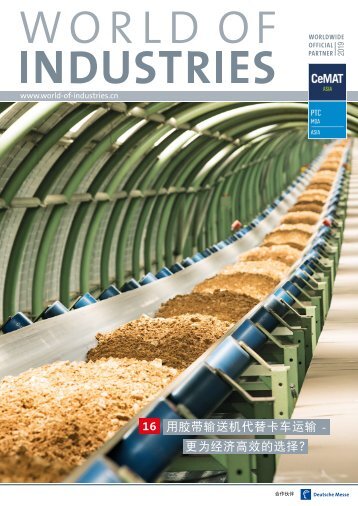

- Page 34 and 35: HANNOVER MESSE WORLDWIDE CeMAT WORL

- Page 36 and 37: Flexibility in every aspect LOGISTI

- Page 38 and 39: Automatic sheet metal storage syste

- Page 40 and 41: 02 Inside, at the front of the ware

- Page 42 and 43: Product launch at TOC Asia in Singa

- Page 44: FAULHABER BHx High performance in t

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...