WORLD OF INDUSTRIES 01/2018

- Text

- Industries

- Brakes

- Components

- Products

- Logistics

- Motors

- Industrial

- Automation

- Solutions

- Measures

RMR measures from

RMR measures from Vanderlande safeguard competitive advantage LOGISTICS E-commerce companies face fierce competition to retain online customers. At a time where same day deliveries are available, factors such as the price, marketing and returns processing are not the only decisive factors when it comes to retaining customers, delivery capabilities and quality must also be considered. Both of these factors are significantly affected by the availability of the intralogistics system. Malfunctions of the intralogistics system or individual system components not only reduce the technical availability of a plant, but in the worst case scenario, they also reduce the delivery capabilities and quality of an e-commerce company. To ensure both of these are maintained at a high level, it must be ensured that the plant is updated on a continuous basis. The revision, modification and retrofit (RMR) method developed by Vanderlande ensures that a high level of plant availability can be guaranteed. High system availability is a decisive factor Intralogistics systems with a high level of availability significantly influence the success of e-commerce companies. It is thus not surprising that most companies strive to achieve technical availability of more than 98 percent. The malfunction of system components or even the complete system have a negative effect on delivery capabilities and quality. Each system failure generates more work to resolve the fault and thus increases the costs. In the worst case scenario, customers do not receive their goods on time, which in turn can result in the loss of customers. The aim is to already achieve a high level of availability during the development of technical facilities and the project planning process. While high-quality and durable components are selected and installed during the development process, the project planning process ensures that the system has a correspondingly redundant design. During operation of the plant, an elaborate maintenance concept and well trained service personnel ensure that the plant is maintained at a high level of availability. However, even a high-quality and well-maintained plant will reach a point when further measures are required to also guarantee a high level of technical availability in the future. 34 WORLD OF INDUSTRIES 2018

like basis, instead parts that have been discontinued or that are no longer available are replaced with new components. Components used in the drive and control technology sector and the IT system are the main focus during this process. Despite the overall system ageing, all three of these measures ensure that a high level of plant availability is guaranteed for the years ahead and that the customer is protected from any unpleasant surprises. Determining causes of malfunctions Durability problems with plant components Generally, all system components have a certain service life that is determined by their design. Mechanical components have a service life of 25,000 to 30,000 operating hours, while the service life of electric components is defined by the number of switching cycles. System components, such as the control system or hard- and software, are not as likely to be affected by durability problems, although it is more likely that they will be discontinued by the manufacturer. These components are then replaced with a new series of products. Especially plants with long operating hours (24/7) will reach the end of their service life relatively quickly, resulting in an increased number of component failures and unscheduled downtimes of the plant. This is why it is sensible to implement a RMR measure no later than this point in time to ensure the plant is fit for the future. Principle of the RMR methodology The RMR measures implemented by Vanderlande cover three areas: Revision: A revision encompasses all of the measures that ensure the original capacity of the system is restored. It consists of a standard, general overhaul during which mechanical and electrotechnical components are replaced with new ones (from the same series). Modification: A modification can include changing the layout, working on the functionality of the control or IT system or improving mechanical system components. Generally, the functionality of the system is adapted. Retrofit: A retrofit is also designed to maintain the technical availability. In contrast to a revision, parts are not replaced on a like-for- Comprehensive RMR measures start with a modification. It is not always possible to adapt the layout or necessary to adjust the control system, although improving mechanical system components can always be taken into consideration. A fault analysis must be completed at the outset to be able to improve specific system components. The supervisory control and data acquisition (SCADA) process records all of the faults over a longer period of time so that the data can be analyzed. The analysis of the data must differentiate between operational faults caused by the customer’s employees and technical faults. The results of the analysis will help determine which areas of the system cause the most or longest malfunctions. As the data cannot provide enough detail about individual areas, the maintenance team must help to determine which individual system components are causing the malfunctions. Once the cause of the malfunction has been determined, a team of experts including process engineers, maintenance technicians, systems engineers and R&D staff can develop technical improvements for the relevant system components. By using newly developed and reliable parts, future malfunctions can be minimized and the availability can be increased. The revision and retrofit processes are then implemented following the modification. The basic approach for these processes is the same, as both of these measures involve the replacement of components (see image). The only difference is that components, which have been discontinued by the manufacturer, must be replaced with new parts (retrofit). Retrofit and revision procedures A ten step plan is implemented as part of the retrofit and revision measures. Step 01 – Analysis of the facilities: During the first step, the layout and bill of materials (BOM) must be used to determine which technical facilities are installed in the system. This step is necessary to ascertain which facilities require a retrofit or revision. Step 02 – Lifetime test: The service life of each individual component within a facility must be determined during the second step. This is usually determined from lifetime sheets that contain the information. In addition, it must be determined how long the system or individual system components have already been operated and whether they have already reached the end of their service life. During this process, it is important to consider the different shift systems and go-live times of plant components. Step 03 – Designation of the parts to be replaced in each facility: This step is used to determine which parts in each of the facilities need to be replaced. Generally, the lifetime sheets already contain recommendations. However, there is also the opportunity to con- WORLD OF INDUSTRIES 2018 35

- Page 1 and 2: www.world-of-industries.com TREND-S

- Page 3 and 4: EDITORIAL Healthy economy - somber

- Page 5 and 6: SOME THINK A MARGIN OF ERROR IS ACC

- Page 7 and 8: Kuebler celebrates its 10 years in

- Page 9 and 10: ened the country’s economic funda

- Page 11 and 12: new international airport in Istanb

- Page 13 and 14: marketing activities and travel con

- Page 15 and 16: Successful in Eastern Europe As of

- Page 17 and 18: IR gas detection sensor ultrasound

- Page 19 and 20: Industrial Ethernet switches Securi

- Page 21 and 22: 01 The Wemo portfolio comprises fou

- Page 23 and 24: Importance for the life sciences in

- Page 25 and 26: Fieldbus module protect man and mac

- Page 27 and 28: 01 The official opening took place

- Page 29 and 30: 01 For many decades, brakes such as

- Page 31 and 32: 01 TC3G - the data management hub i

- Page 33: The next generation of integrated s

- Page 37 and 38: Linde Material Handling launched a

- Page 39 and 40: 01 At Sanofi, up to 60 pallets per

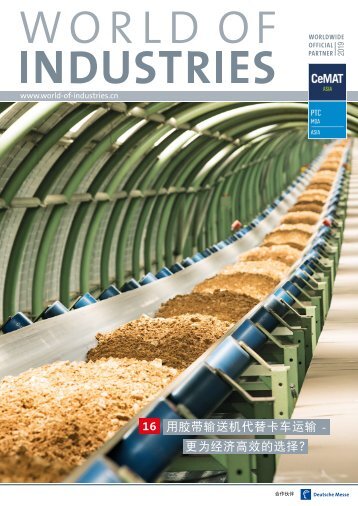

- Page 41 and 42: Alternative fuels instead of primar

- Page 43 and 44: 02 With its ability to navigate hor

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...